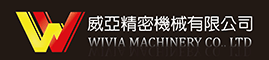

Single Y axis Swiss Turn CNC Machine W327 / 427

Home > W Series (32 / 42) > Single Y axis Swiss Turn CNC Machine W327 / 427

W327 / 427

Description

Wivie always think about needs and conveniences from users, and then, we make more suitable and efficient machines, W series. The human-based and innovation are our important core design. The new experience by W series presented.

W series and SW series CNC Swiss Turn Machine can process milling, tapping, drilling, and turning complexity parts for medial parts (especially for bone screw), electrical parts, automobile, clock/ watch, and aerospace..., etc.. Main and Sub spindle synchronous machining can save time cost.

W327 / 427 New Single Y axis Swiss Turn Machine Catalog

Feature

Process Capacity:

|

Item |

Unit |

Max. Capacity |

Remark |

|

Main/ Sub spindle Max. drilling |

mm |

Ø13 |

SUS303 |

|

Main/ Sub spindle Max. tapping |

mm |

M12 / P1.75 |

SUS303 |

|

Cross live tool Max. drilling |

mm |

Ø10 |

SUS303 |

|

Cross live tool Max. tapping |

mm |

M8 / P1.25 |

SUS303 |

|

Sub spindle face live tool Max. drilling |

mm |

Ø10 |

SUS303 |

|

Sub spindle face live tool Max. tapping |

mm |

M6 / P1.0 |

SUS303 |

*Tested by FANUC system

Specification Table

Main structure:

|

Item |

Unit |

W327 |

W427 |

Remark |

|

Max. turning dia. |

mm |

Ø32 |

Ø42 |

|

|

Max. turning length (Rotary) |

mm |

300 |

|

|

|

Max. turning length (Fixed) |

mm |

340 |

|

|

|

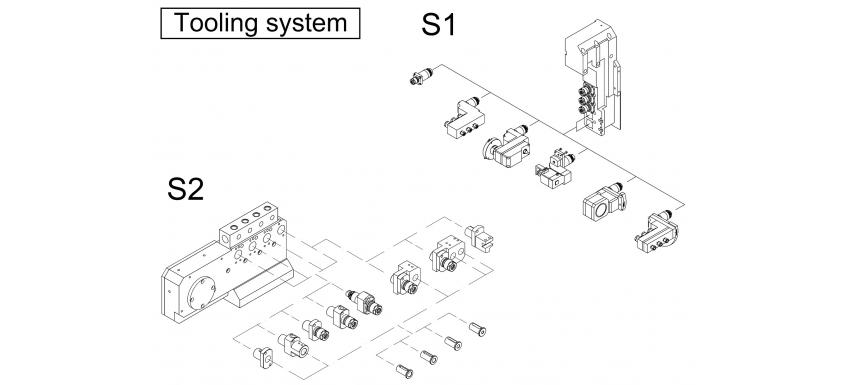

Max. turning length (Non guide bush) |

mm |

80 |

105 |

|

|

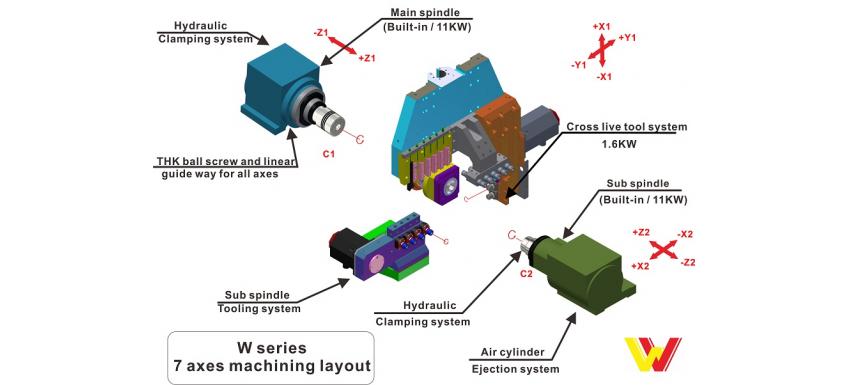

OD tooling holder |

pcs |

6 |

□16 |

|

|

ID tooling holder |

pcs |

5 |

Ø25 |

|

|

Cross live tooling holder |

pcs |

3 |

ER-20 |

|

|

Cross live tooling holder |

pcs |

2 |

ER-16 |

|

|

Face live tooling of sub spindle holder |

pcs |

4 |

4 |

ER-16 |

|

Sub spindle aside drilling tooling holder |

pcs |

2 |

Ø25 |

|

|

No. of axis controls (with C axis) |

pcs |

7 |

7 |

|

|

C axis control minimum |

degree |

0.001° |

|

|

|

Max. main spindle speed |

rpm |

7000 |

6000 |

|

|

Max. sub spindle speed |

rpm |

7000 |

6000 |

|

|

Rapid traverse of X1/X2/Z1/Z2/Y1 |

M/min |

30 |

|

|

|

Rapid traverse of Y2 |

M/min |

20 |

|

|

|

Main spindle motor |

KW |

11 |

Built-in |

|

|

Sub spindle motor |

KW |

11 |

Built-in |

|

|

Main spindle cooling |

pcs |

Oil cooling |

|

|

|

Sub spindle cooling |

pcs |

Oil cooling |

|

|

|

Main spindle clamping system |

pcs |

Hydraulic |

|

|

|

Sub spindle clamping system |

pcs |

Hydraulic |

|

|

|

Cross live tooling motor |

KW |

1.6 / 6000rpm |

|

|

|

Face live tooling motor of sub spindle |

KW |

1.4 / 6000rpm |

|

|

|

Lubrication tank |

L |

2 |

|

|

|

Air compressed pressure |

Mpa |

0.6 |

1 | |

|

Air compressed flow |

L/min. |

20 ~ 145 |

4 |

|

|

Machine dimension L x W x H |

mm |

2945 x 1665 x 2130 |

2 |

|

|

Coolant tank |

L |

380L(100%) |

3 | |

|

Weight |

KG |

4450 |

2 | |

1. 0.6Mpa = 6kg/cm2

2. Without coolant tank and pumps.

3. At least 90% full for machining

4. Air flow will be different by different options.

All specification are subject to change without notice.